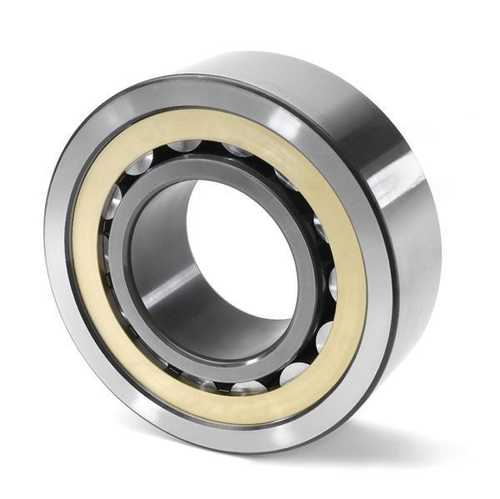

Cylindrical Roller Bearing Supplier In Mumbai | Sadguru International In Mumbai

Tips For Bearing Maintenance

For Cylindrical Roller Bearing Supplier In Mumbai Contact Sadguru International In Mumbai

Whenever a bearing is used for mounting, it is crucial that the housing and shaft are inspected for any sort of physical condition or damage. Always use a soft cloth to wipe the surfaces clean and make sure any nicks and burrs are removed.

Many different devices rely on bearings to operate. If those bearings are not properly maintained, the device will not be able to perform at its peak level, and it could end up causing damage if left unchecked for too long.

For that reason, we have gathered some tips and tricks for bearing maintenance to ensure a longer expected lifespan, reduced downtime, and improved productivity, all of which save your business money in man hours and repair costs.

One main factor in bearing performance is ensuring the proper bearing is specified for the given application.

Each bearing has a unique set of design characteristics and options that may not necessarily be determined simply by looking at, or even handling, the old bearing. Sometimes the right bearing is not used to begin with, further complicating the choice moving forward.

Damage to the bearing can be detected early by measuring thevibration of the machine. The degree of damage is inferred fromquantitative analysis of the amplitude and frequency of thevibration.

However, values measured differ depending on the measuring point and the operating condition of the bearing. It is desirable to accumulate measurement data and establish evaluation criteria for each machine.

The rolling-contact bearing is an element of machinery with a very important role, and it dominates the performance of the machine. If one of the bearings breaks or seizes, not only the machine but also the assembly line may stop. If one of the axle bearings of an automobile or a railway car breaks down, a serious accident could occur.

When a bearing is ready to be mounted, maintenance staff should confirm that shaft and housing are clean, undamaged, and dimensionally accurate, with proper fit and tolerance; lubricant is clean and correctly specified; necessary tools and equipment are on hand; and safety precautions are in place.

The method used to mount the bearings depends on the type of bearing. For example, bearings with cylindrical bores are generally mounted through a press fit method.

Bearings with tapered bores can be mounted directly on tapered or cylindrical shafts with the use of tapered sleeves. However, pressure should be applied only with a press fit because without it the raceways can become damaged.

In many cases, the best way to identify the critical specifications is by understanding the bearing’s product designation marked on the side faces of the bearing.

For example, if a technician only looks at a numeral designation—without the additional suffixes—the selected bearing may be provided with the incorrect design feature such as the improper level of internal clearance.

The maximum heating allowed on the bearings depends on the heat treatment of the material. If they are heated above the permitted limit, they can permanently deform or soften the bearing steel, lowering load carrying capacity and resulting in a failure. Always heat the bearings using induction heaters, and never with an open flame.

Manufacturing facilities collect dust and other contaminants. Despite the surroundings, it is crucial to establish a clean workspace prior to bearing installation.

This prevents harmful elements from contacting the bearing before it is commissioned. An oft-forgotten but common-sense tip is to keep the box containing the new bearing closed until it is ready for mounting to avoid any ingress of contaminants.

Every bearing becomes unserviceable in the course of time even if it is installed correctly and operated properly. The raceway surfaces and the rolling contact surfaces of the rolling elements are repeatedly subjected to compressive loads, and the surfaces eventually flake.

Bearings are precision components. As such, they should be handled and stored in a proper manner to avoid the entry of contaminants.

Bearings should be stored horizontally in a clean and dry environment with their packaging intact. Care should be taken to avoid exposing bearings to airborne contaminants, as just a tiny speck of dirt in a raceway can cause premature bearing failure.

Do not hammer, pound or apply direct force on a bearing or its outer ring. This can cause the rolling elements to be damaged and misaligned.

Bearings should also not be installed if they have been dropped or mishandled, as little cracks and scratches can result in poor performance, and subsequently, premature bearing failure.

Half of all bearing failures attributed to poor lubrication are caused by selection of an inadequate grease type for the operating conditions or to mixing incompatible greases with different properties.

Therefore, it is imperative for optimized bearing performance that the correct type of grease be selected to deliver the necessary base oil viscosity in the proper amount at the prevailing operating temperature.

Select the suitable lubricant. This will help bearings perform as long as intended. Good lubricants primarily provide a separating film between a bearing’s rolling elements, raceways, and cages to prevent metal-to-metal contact and undesired friction that otherwise would generate excessive heat that could cause wear, metal fatigue, and potential fusing of the bearing contact surfaces.

Large bearings cannot be rotated manually; however, the rolling elements, raceway surfaces, cages, and contact surface of the ribs should be carefully examined visually. The more important a bearing is, the more carefully it should be inspected.

Specialized tools like bearing pullers, bearing fitting tool kits, oil injector kits, hydraulic nuts, or induction heaters should be used in the mounting and dismounting processes. These tools ensure the smooth process of mounting or dismounting, in order to minimize the risk of damage.

Different types of bearings require different methods to mount them, and the type of fit will change the mounting as well. If you’re using a bearing with a cylindrical bore, it is typically mounted using the press fit method, in which it is mounted by pressing the bearing on the shafts, or with the shrink fit method, where heat is applied in a specific way to expand the bearing’s diameter.

A bearing with a tapered bore can be mounted directly either on tapered or cylindrical shafts, through the use of tapered sleeves.

It is important to remember, pressure should only be applied with a press fit. If you apply pressure without a press fit to the ring, the raceways will be damaged and the bearing will not operate as intended.